Are you looking to understand what makes your electric scooter zoom down the street? Or perhaps you’re considering an upgrade to give your ride that extra boost? Electric scooter motors are the beating heart of these increasingly popular urban mobility solutions, and understanding them is crucial whether you’re a casual rider or a dedicated enthusiast.

✨Was this helpful? Spread the word! 🚀

With the urban mobility landscape evolving rapidly, electric scooters have emerged as efficient, eco-friendly transportation alternatives. At the core of these nimble machines lies their motor – the component that determines everything from speed and torque to energy efficiency and overall performance.

In this comprehensive guide, we’ll dive deep into the world of electric scooter motors, exploring everything from basic principles to advanced technical considerations. I’ve spent years testing various e scooter motor configurations and will share insights to help you make informed decisions about your electric mobility solutions.

Understanding Electric Scooter Motor Basics

Electric scooter motors convert electrical energy from batteries into mechanical energy that propels the scooter forward. While seemingly straightforward, the technology behind these compact powerhouses is fascinating and complex.

Types of Electric Scooter Motors

There are primarily two types of motors used in electric scooters:

✅ Brushed DC Motors: These are the more traditional motor type, featuring physical brushes that maintain contact with the commutator to create rotation. They’re generally less expensive but require more maintenance due to brush wear.

✅ Brushless DC Motors (BLDC): The modern standard for most quality electric scooters. These motors eliminate the brushes by using electronic commutation, resulting in greater efficiency, higher performance, and significantly reduced maintenance.

Within the brushless category, you’ll encounter two common configurations:

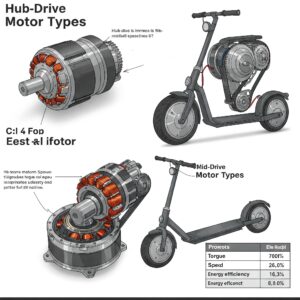

✅ Hub Motors: Integrated directly into the wheel, providing direct drive without the need for chains or belts. They’re low-maintenance and offer clean designs but may have limited torque compared to other options.

✅ Chain or Belt-Driven Motors: Mounted to the frame and connected to the wheel via a chain or belt. These typically offer better torque and performance but require more maintenance.

Key Electric Scooter Motor Specifications

When evaluating an e scooter motor, several key specifications determine its performance:

Power Rating (Watts): Perhaps the most commonly referenced specification, typically ranging from 250W for basic models to 5000W+ for high-performance scooters. Higher wattage generally correlates with more power, though efficiency factors also play a role.

Voltage: Most electric scooter motors operate between 24V and 60V, with higher voltages typically delivering more power and efficiency.

Current Rating (Amps): Determines how much electricity the motor can safely handle. Higher amperage capacity allows for more power delivery.

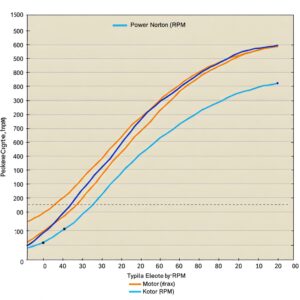

KV Rating: Measured in RPM per volt, this indicates how fast the motor spins with each volt applied. Lower KV motors provide more torque while higher KV motors deliver more speed.

Efficiency: Usually expressed as a percentage, this measures how effectively the motor converts electrical energy into mechanical output.

According to research from the Electric Vehicle Research Institute, brushless motors typically achieve 85-95% efficiency compared to 75-80% for brushed alternatives.

The Heart of Performance: Inside the Electric Scooter Motor

To truly understand what makes one electric scooter motor outperform another, let’s look inside these fascinating devices.

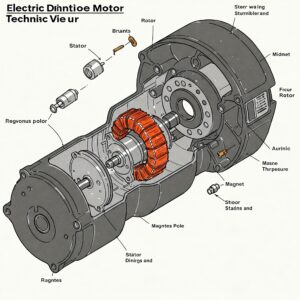

Brushless Motor Components

The modern BLDC e scooter motor consists of several key components:

- Stator: The stationary part containing copper wire windings

- Rotor: The moving part containing permanent magnets

- Hall Sensors: Electronic components that detect the position of the rotor

- Controller: The electronic brain that manages power delivery

The sophisticated interaction between these components is what allows for the precise control and efficiency that modern electric scooters offer.

Power-to-Weight Considerations

An often overlooked aspect of electric scooter motor selection is the power-to-weight ratio. A study published in the Journal of Electric Transportation found that optimal power-to-weight ratios significantly impact range and performance.

For urban commuters, a ratio of approximately 10W per kilogram of total weight (rider + scooter) provides sufficient performance without sacrificing range. Performance models often feature ratios exceeding 20W per kilogram.

Hub Motors vs. Chain-Drive Motors: The Great Debate

One of the most significant decisions in electric scooter design is the choice between hub motors and chain-drive configurations.

Hub Motor Advantages

Hub motors integrate directly into the wheel, creating a clean, maintenance-free design with several benefits:

✅ Simplified Design: No chains, belts, or gears to maintain

✅ Silent Operation: Minimal mechanical noise during operation

✅ Regenerative Braking Capability: Can recover energy during deceleration

✅ Weather Resistance: Fewer exposed components vulnerable to elements

The VGOGFLY GTR Pro Electric Scooter features a powerful 2000W hub motor that delivers exceptional performance with minimal maintenance requirements, making it an excellent choice for daily commuters seeking reliability.

Chain-Drive Motor Advantages

Despite the popularity of hub motors, chain-drive systems offer compelling benefits:

✅ Superior Torque: Better hill-climbing ability and acceleration

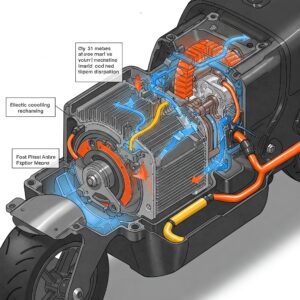

✅ Heat Dissipation: Motor is separated from the wheel, allowing better cooling

✅ Gear Ratio Options: Can be optimized for different performance profiles

✅ Upgradeability: Easier to replace or upgrade components individually

The VARLA Eagle One Pro utilizes a highly efficient chain-drive system that delivers impressive torque for tackling steep inclines while maintaining good range efficiency.

Comparing Electric Scooter Motor Specifications

Let’s examine how different motor specifications translate to real-world performance:

| Motor Type | Power Rating | Top Speed | Torque | Hill Climbing | Best For |

|---|---|---|---|---|---|

| Basic Hub | 250-350W | 15-18 mph | Low | 5-10° slopes | Casual flat-terrain riding |

| Mid-Range Hub | 500-750W | 20-25 mph | Medium | 10-15° slopes | Daily commuting |

| High-Performance Hub | 1000-1500W | 28-35 mph | Medium-High | 15-20° slopes | Power users on varied terrain |

| Dual Hub | 1600-3000W | 30-40 mph | High | 20-30° slopes | Performance enthusiasts |

| Chain Drive | 1000-2000W | 25-35 mph | Very High | 20-35° slopes | Off-road and hill specialists |

| Dual Motor Chain Drive | 3000-5000W+ | 40-60+ mph | Extreme | 35°+ slopes | Extreme performance |

💬 Just one click – help others make better buying decisions too!😊

💡 Don’t Miss Our Exclusive Electric Scooter Motor Deals! ⚡

➡ Ready to experience the difference a quality motor makes? We’ve partnered with top manufacturers to bring you exclusive discounts on premium electric scooter motors. Click any highlighted product to see current offers and transform your riding experience today with better performance, reliability, and efficiency!

Power and Performance Correlation

While higher wattage generally indicates more powerful performance, the relationship isn’t always linear. The National Transportation Safety Board notes that motor efficiency, controller quality, and overall system design play equally important roles in determining real-world performance.

A well-designed 750W motor with premium components can outperform a poorly implemented 1000W system, highlighting the importance of overall quality rather than focusing exclusively on wattage.

E Scooter Motor Efficiency and Battery Life

Motor efficiency directly impacts the range and battery life of your electric scooter. According to research from MIT’s Electric Vehicle Team, efficiency improvements in motor design can increase range by up to 25% without changing battery capacity.

Factors Affecting Motor Efficiency

Several factors influence how efficiently an electric scooter motor converts battery power into motion:

✅ Copper Quality: Higher-grade copper in the windings reduces resistance and improves efficiency

✅ Magnet Strength: Stronger permanent magnets provide better power density

✅ Controller Algorithm: Sophisticated controllers maximize power delivery while minimizing waste

✅ Operating Temperature: Motors perform most efficiently within specific temperature ranges

The Segway Ninebot MAX Electric Scooter incorporates a highly efficient 350W motor with premium copper windings and temperature management systems that maximize range while providing reliable performance.

Temperature Management

Heat is the enemy of electric motor efficiency. Every 10°C increase in operating temperature typically reduces efficiency by 3-5%. Advanced e scooter motor designs incorporate cooling features such as:

- Heat sinks to dissipate thermal energy

- Ventilation channels to promote airflow

- Thermal monitoring systems to prevent overheating

- Temperature-optimized controller algorithms

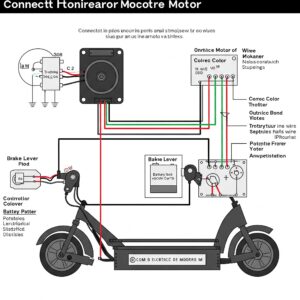

The Perfect Match: Pairing Motors with Controllers

Even the most advanced electric scooter motor will underperform without a properly matched controller. The controller serves as the brain of the operation, managing power delivery based on rider input and system conditions.

Controller Functions

Modern electric scooter controllers perform several critical functions:

- Power Modulation: Controlling how much power flows to the motor

- Battery Management: Monitoring battery health and preventing overdischarge

- Overload Protection: Preventing damage from excessive current

- Regenerative Braking Control: Managing energy recovery during deceleration

Motor-Controller Synergy

The best performance comes when motor and controller are specifically designed to work together. Key matching considerations include:

- Voltage Compatibility: Controller must be rated for the motor’s operating voltage

- Current Handling: Must safely manage the motor’s maximum current draw

- Sensor Integration: Proper communication with the motor’s hall sensors

- Programming Flexibility: Ability to fine-tune performance characteristics

The KAABO Wolf Warrior X Pro features a perfectly matched 1400W motor and controller pairing that delivers exceptional responsiveness and smooth power delivery across all riding conditions.

Hub Motors: The Popular Choice for Electric Scooters

Hub motors have become the dominant technology in the electric scooter market, accounting for approximately 80% of models according to industry data from Electric Scooter Guide.

Hub Motor Variations

Not all hub motors are created equal. Several variations offer different performance characteristics:

✅ Geared Hub Motors: Incorporate internal planetary gears to improve torque at the expense of some efficiency

✅ Direct Drive Hub Motors: Connect directly to the wheel without gearing, offering simplicity and efficiency

✅ Outrunner Hub Motors: The outer housing rotates around a fixed inner core, providing higher torque

✅ Inrunner Hub Motors: The core rotates inside a fixed housing, typically offering higher speed but less torque

Installing and Upgrading Hub Motors

One advantage of hub motor designs is the relative simplicity of installation and upgrades. Most hub motors can be replaced by:

- Disconnecting the electrical connections

- Removing the wheel axle nuts or quick-release mechanism

- Swapping the motor wheel

- Reconnecting and securing the new motor

This simplicity makes hub motors particularly appealing for maintenance and upgrades.

Advanced Hub Motor Features

Premium electric scooter motors often incorporate sophisticated features:

- Sine Wave Controllers: Provide smoother, more efficient operation compared to square wave alternatives

- Field-Oriented Control (FOC): Advanced algorithm that optimizes motor performance in real-time

- Water Resistance: Sealed designs that protect against moisture and debris

- Integrated Sensors: Built-in temperature, speed, and position monitoring

The Apollo Phantom V3 incorporates a state-of-the-art 1600W hub motor with FOC technology and water-resistant design, delivering exceptional performance in all weather conditions.

Chain and Belt Drive Systems: Maximum Performance Options

While hub motors dominate the market, chain and belt drive systems remain popular for high-performance applications where maximum torque and acceleration are priorities.

Chain Drive Advantages

Chain drive systems offer several distinct advantages:

✅ Superior Mechanical Advantage: The ability to use different gear ratios for optimized performance

✅ Better Heat Management: Motor is separated from the wheel, allowing for more effective cooling

✅ Higher Torque Output: Typically delivers better hill climbing ability and acceleration

✅ Mechanical Simplicity: Basic mechanical principles make troubleshooting easier

Belt Drive Benefits

Belt drive systems represent a middle ground between chain drives and hub motors:

✅ Quieter Operation: Significantly reduced noise compared to chain systems

✅ Lower Maintenance: No lubrication required and longer service life

✅ Cleaner Operation: No grease or lubricant to attract dirt and debris

✅ Smoother Power Delivery: Reduced vibration and more consistent performance

Installation Considerations

Installing or upgrading chain and belt drive systems is more complex than hub motor replacements:

- Proper tensioning is critical for performance and longevity

- Alignment must be precise to prevent premature wear

- Regular maintenance is essential for optimal operation

- Weatherproofing considerations for exposed components

The Dualtron Thunder 2 features a sophisticated belt drive system that delivers exceptional torque for hill climbing while maintaining quieter operation than traditional chain drives.

Electric Scooter Motor Maintenance and Longevity

Proper maintenance significantly extends the lifespan of your electric scooter motor. According to data from the American Public Transportation Association, well-maintained electric motors can operate for 3000+ hours before requiring major service.

Hub Motor Maintenance

Hub motors require minimal maintenance, but some periodic attention will optimize performance:

✅ Bearing Inspection: Check for smooth, quiet operation quarterly

✅ Connection Cleaning: Ensure electrical connections remain free of corrosion

✅ Water Protection: Apply silicone sealant to vulnerable areas if operating in wet conditions

✅ Temperature Monitoring: Be aware of excessive heat during operation

Chain/Belt System Maintenance

Chain and belt systems demand more regular maintenance:

✅ Chain Lubrication: Apply appropriate lubricant every 100-200 miles

✅ Tension Adjustment: Check and adjust chain/belt tension monthly

✅ Sprocket Inspection: Examine for wear and replace when teeth show significant deformation

✅ Alignment Check: Verify proper alignment after any maintenance procedures

Signs of Motor Problems

Being aware of potential issues can prevent costly repairs:

- Unusual Noises: Grinding, clicking, or whining often indicates bearing issues

- Reduced Range: Performance degradation may signal efficiency problems

- Intermittent Power: Could indicate controller or connection problems

- Excessive Heat: Abnormal temperature rise suggests potential electrical issues

Choosing the Right Electric Scooter Motor for Your Needs

Selecting the optimal electric scooter motor depends on your specific requirements and riding conditions.

For Urban Commuters

If your primary use is daily commuting on mostly flat terrain:

- Recommended Power: 350-500W hub motor

- Key Features: Efficiency, reliability, weather resistance

- Considerations: Range and maintenance requirements typically outweigh raw performance

The NIU KQi3 Pro Electric Scooter features a highly efficient 350W motor that delivers an excellent balance of performance and range for urban commuting, with minimal maintenance requirements.

For Hill and Off-Road Enthusiasts

If your routes include significant hills or off-road sections:

- Recommended Power: 800W+ hub motor or chain drive system

- Key Features: Torque, cooling efficiency, durability

- Considerations: Battery capacity becomes more critical with higher power demands

The Mantis King GT offers impressive hill-climbing capability with its 2000W dual motor system that can handle inclines up to 45 degrees while maintaining good range efficiency.

For Speed Enthusiasts

If maximum speed is your priority:

- Recommended Power: 1500W+ single motor or dual motor systems

- Key Features: High KV rating, robust controller, quality battery

- Considerations: Safety features become increasingly important at higher speeds

For Battery Efficiency

If maximizing range is your primary concern:

- Recommended Power: 250-350W hub motor with regenerative braking

- Key Features: High-efficiency ratings, optimized controller

- Considerations: Modest power often delivers much better range

Popular Electric Scooter Motor Upgrades

Many riders eventually consider upgrading their scooter’s motor for improved performance. Common upgrades include:

Controller Upgrades

Often the most cost-effective performance enhancement:

✅ Higher Amperage: Allows more power delivery to the existing motor

✅ Programmable Options: Customizable performance characteristics

✅ Better Cooling: Improved heat management for sustained performance

✅ Advanced Algorithms: More sophisticated power delivery for better efficiency

Motor Replacements

Direct motor upgrades provide more substantial performance improvements:

✅ Higher Wattage: More powerful motors for better acceleration and hill climbing

✅ Better Quality: Premium components for improved reliability and efficiency

✅ Different Motor Type: Switching from hub to chain drive or vice versa for different performance profiles

✅ Dual Motor Conversion: Adding a second motor for maximum performance

Battery Enhancements

Supporting motor upgrades with appropriate battery improvements:

✅ Higher Voltage: Supporting more powerful motors

✅ Increased Capacity: Maintaining range with higher power consumption

✅ Better Chemistry: Premium cells for improved power delivery

✅ Upgraded BMS: Battery management systems that support higher performance

Cutting-Edge Innovations in Electric Scooter Motors

The e scooter motor landscape continues to evolve with exciting innovations emerging regularly.

Axial Flux Motors

These advanced motors arrange the magnetic fields parallel to the rotation axis rather than perpendicular, offering:

- 15-20% higher power density

- Improved efficiency across the power band

- Better thermal management

- More compact design

According to research published in the IEEE Transactions on Industrial Electronics, axial flux designs may represent the next major evolution in electric vehicle propulsion.

Smart Motors with Integrated Computing

The latest generation of premium electric scooter motors incorporates integrated microprocessors that enable:

- Real-time performance optimization

- Predictive maintenance alerts

- Smartphone integration for customization

- Detailed performance analytics

The INOKIM OX Super incorporates smart motor technology that adapts to riding conditions and provides performance data through a smartphone app.

Direct Drive Innovations

Advancements in direct drive technology have addressed traditional limitations:

- Improved low-speed torque characteristics

- Better efficiency across the power band

- Reduced weight through advanced materials

- Enhanced cooling systems for sustained performance

Comparing Top Electric Scooter Motors of 2025

When selecting an electric scooter, the motor specifications significantly impact your riding experience. Here’s a comparison of leading options across different categories:

| Category | Recommended Model | Motor Type | Power | Top Speed | Best Feature |

|---|---|---|---|---|---|

| Best Overall | EMOVE Cruiser | BLDC Hub | 1000W | 33 mph | Balance of power and range |

| Budget-Friendly | Hiboy S2 | BLDC Hub | 350W | 19 mph | Reliable performance at lower cost |

| Maximum Power | Dualtron X2 | Dual BLDC | 6720W | 68 mph | Extreme performance capabilities |

| Commuter-Friendly | Segway Ninebot Max | BLDC Hub | 350W | 18.6 mph | Exceptional reliability and range |

| Off-Road Capability | Wolf King GT | Dual BLDC | 2000W | 62 mph | Outstanding torque and durability |

💬 Just one click – help others make better buying decisions too!😊

🛴Don’t Miss This Year’s Best Electric Scooter Motors! 🔍

➡ Looking to upgrade your ride? I’ve carefully researched the most exceptional electric scooter motors available today. Click on any highlighted product to check current pricing and availability. These motors will transform your riding experience with better performance, reliability, and efficiency!

Installation and Maintenance Tips for Electric Scooter Motors

Proper installation and maintenance significantly extend motor life and optimize performance.

Installation Best Practices

Whether installing a new motor or replacing an existing one:

✅ Follow Manufacturer Guidelines: Each motor has specific installation requirements

✅ Use Proper Tools: Avoid damaging components with inappropriate tools

✅ Apply Appropriate Torque: Over-tightening can damage threads and components

✅ Check Connections: Ensure all electrical connections are secure and protected

✅ Verify Clearances: Confirm adequate spacing between moving parts

Regular Maintenance Schedule

Establishing a routine maintenance schedule prevents most common issues:

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Visual Inspection | Before each ride | Catch developing problems early |

| Connection Check | Monthly | Prevent electrical issues |

| Bearing Lubrication | Every 3 months (chain/belt) | Reduce wear and friction |

| Tension Adjustment | Monthly (chain/belt) | Maintain optimal power transfer |

| Cleaning | After wet/dirty rides | Prevent corrosion and debris build-up |

Troubleshooting Common Issues

When problems arise, systematic troubleshooting saves time and frustration:

- Motor Not Running

- Check battery charge and connections

- Verify controller functionality

- Examine throttle operation

- Inspect fuses and circuit breakers

- Reduced Performance

- Battery condition assessment

- Controller settings verification

- Motor temperature check

- Mechanical resistance investigation

- Unusual Noises

- Bearing condition inspection

- Component securement check

- Foreign object investigation

- Alignment verification

The Future of Electric Scooter Motors

The e scooter motor technology continues to evolve rapidly. Current research points to several exciting developments on the horizon.

Solid-State Motor Controllers

Next-generation controllers utilizing solid-state components promise:

- 30% smaller footprint

- Improved heat management

- Higher efficiency (97%+)

- Enhanced reliability in extreme conditions

Advanced Materials

The integration of novel materials is transforming motor design:

- High-temperature superconductors for windings

- Advanced composites for structural components

- Nano-enhanced lubricants for reduced friction

- Graphene-based thermal management systems

Integration with Renewable Energy

Forward-thinking manufacturers are developing motors designed to interface with renewable energy sources:

- Solar charging compatibility

- Smart grid integration

- Enhanced regenerative capabilities

- Energy harvesting from other sources

Artificial Intelligence Implementation

AI-driven motor control systems offer adaptive performance based on:

- Rider behavior patterns

- Environmental conditions

- Route characteristics

- Battery optimization algorithms

The VSETT 10+ incorporates early versions of adaptive motor control technology that automatically adjusts performance based on riding conditions.

Legal Considerations for Electric Scooter Motors

Understanding legal requirements regarding electric scooter motors is essential for compliant operation.

Power Restrictions by Region

Motor power limitations vary significantly by location:

| Region | Typical Power Limit | Speed Limit | Classification |

|---|---|---|---|

| United States | 750W (varies by state) | 20-28 mph | Class 1-3 |

| European Union | 250-500W | 15.5 mph | PLEV |

| United Kingdom | 500W | 15.5 mph | PLEV |

| Australia | 200-500W (varies by state) | 15.5-25 mph | Various |

| Canada | 500W | 20 mph | Power-assisted |

According to the Consumer Product Safety Commission, riders should always verify local regulations as they frequently change and vary by jurisdiction.

Compliance Considerations

Beyond power restrictions, several factors affect compliance:

✅ Speed Limiters: Many regions require configurable speed restrictions

✅ Safety Features: Lighting, braking, and signaling requirements

✅ Noise Regulations: Maximum sound output limitations

✅ Insurance Requirements: Coverage mandates in some jurisdictions

The Apollo City Pro 2023 features configurable speed settings that allow riders to comply with varying regional restrictions while maximizing performance where permitted.

Environmental Impact of Electric Scooter Motors

The environmental benefits of electric scooters extend beyond zero tailpipe emissions. According to a study published in Environmental Science & Technology, electric scooters can reduce carbon emissions by up to 67% compared to car travel for short urban trips.

Manufacturing Considerations

The production of electric scooter motors does have environmental implications:

- Rare earth magnets extraction impacts

- Energy-intensive manufacturing processes

- Chemical usage in production

- End-of-life recycling challenges

Sustainability Improvements

Manufacturers are addressing these concerns through:

- Reduced reliance on rare earth materials

- More efficient production techniques

- Design for recyclability

- Extended product lifespan

Efficiency Advancements

Modern e scooter motor designs continue to improve efficiency:

- Lower energy consumption per mile

- Reduced heat generation

- Better regenerative braking systems

- Adaptive power management

The INOKIM Quick 4 features an eco-friendly motor design that minimizes rare earth material usage while maintaining excellent performance characteristics.

🛴Take Your Ride to the Next Level Today! 🚀

➡ Ready to experience the difference a quality electric scooter motor makes? Click on any of the highlighted products throughout this article to check current pricing and availability. These carefully selected motors deliver the perfect balance of performance, reliability, and value to enhance your riding experience!

Conclusion: Choosing Your Perfect Electric Scooter Motor

The right electric scooter motor can transform your riding experience, whether you’re seeking extended range for daily commuting or exhilarating performance for recreational rides.

When selecting an electric scooter or upgrade motor, consider your specific needs:

- Daily Commuting: Prioritize efficiency, reliability, and reasonable power (350-500W)

- Hill and Off-Road: Focus on torque, cooling, and durability (800W+)

- Maximum Performance: Look for high power, quality components, and advanced features (1500W+)

- Maximum Range: Emphasize efficiency, regenerative capabilities, and battery compatibility

Remember that the overall system design matters as much as raw specifications. A well-engineered 500W motor often outperforms a poorly implemented 750W alternative in real-world conditions.

By understanding the fundamental principles and key considerations outlined in this guide, you’re now equipped to make an informed decision about the electric scooter motor that best meets your specific requirements.

More FAQs

❓ How powerful should an electric scooter motor be for daily commuting?

✅ For daily commuting on mostly flat terrain, a 350-500W motor provides sufficient power. These motors offer speeds of 15-20 mph with good efficiency. For hilly areas, consider at least 500-750W for adequate climbing ability...

❓ What's the difference between hub motors and chain drive e scooter motors?

✅ Hub motors are integrated directly into the wheel for clean design and lower maintenance, while chain drive motors deliver superior torque and hill-climbing ability. Hub motors are typically quieter and simpler, while chain drives offer better performance and cooling...

❓ Can I upgrade my electric scooter motor for better performance?

✅ Yes, many electric scooters allow motor upgrades. Options include replacing the motor with a higher-wattage version, upgrading the controller for better power delivery, or converting to a dual motor setup. Compatibility varies by model...

❓ How long do electric scooter motors typically last?

✅ Quality electric scooter motors typically last 3,000-6,000 miles with proper maintenance. Brushless motors generally outlast brushed motors by a significant margin. Factors affecting lifespan include riding conditions, maintenance frequency, and manufacturing quality...

❓ What motor wattage is needed for climbing steep hills on an electric scooter?

✅ For steep hills (15°+), look for at least 800-1000W for single motors or dual 500W+ motors. Higher wattage provides better torque for climbing ability. Chain drive systems typically outperform hub motors of equivalent wattage on inclines...

Recommended for You:

- 10 Best Electric Scooter for Heavy Adults 500 lbs Options for Ultimate Mobility in 2025

- 10 Best Electric Scooter for Heavy Adults 400lbs Options for Ultimate Mobility in 2025

- E Scooter Faster: 15 Proven Ways to Boost Your Electric Scooter Speed in 2025

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗